NEGATIVE MOLDS OF FOOT THROUGH THE APPLICATION OF A THERMOPLASTIC.

We were the pioneers fifteen years ago in the use of thermoplastics for making negative molds. We want to spread in this issue a good alternative in order to make molds.

It is a fact about the variety of existing methods for the making of foot molds such as the empty system, the phenolic foam, charging system, etc. But most of us agree that one of the most reliable systems for making a negative mold and probably the most used, is the application of plaster bandage on the foot in prone or supine decubitus. If it is in fact one of the most accurate systems, why not to improve it?. Have you ever thought about the possibility of using a material with the same features than the plaster bandage but without its disadvantages?

The biodegradable thermoplastic has all this kind of features. This material consists of such thermoplastic joined to a carrier of pure cotton. The methodology will be identical to the use of plaster bandage, because as we have said before, this material has the same features than the mentioned bandage about setting time, adherence, flexibility, etc. The only difference with respect to the plaster bandage is, that for its adaptation, it must be inserted in water at a temperature of 70º C for five seconds.

Once is executed what we have explained before, we extract it from water with forceps, with the purpose of not being burnt ourselves. Once the material is removed from water we shake it softly, with hands, in order to remove the remaining water. Don’t be afraid of burning your hands because this material absorbs little water and thus, keeps very few hot.

When the mold has been made, we will adapt the plantar support on it, previously with a glass fiber layer, this works like a separator engine between the mold and the plantar support. We use an antithermic material to avoid that the heat of the material to be adapted doesn’t soften the mold again, causing in this way irregularities in the plantar support. Other thermal insulators can be used like for example the Triton Kawool. We use this material as an insulator because it absorbs the heat 50º more than glass fiber.

Another advantage is its economic profitability in relation with the glass fiber, and being a uniform surface material, we can adapt plantar supports through vacuum use without marked irregularities in the same ones (for example, the polypropylene). As a comparison, we can say that the thickness of a Triton Kawool blade is equivalent to the glass fiber layers. It consists of a thin cloth impregnated of tiny ceramic glasses. In the market it exists different kind of thickness.

When this technique is over, we can reutilize the mold with another patient, previously disinfecting it. To make positive molds with this material we have to cover the internal side of the mold with a very thin plastic before pouring the liquid plaster and when it has been forged, we can extract and polish the irregularities from the surface. There are the following advantages for the podiatrist:

- Immediate flexibility in the water at 70º C., it can be possible to be adapted in any area of the foot.

- Easy material to cut in cold or hot.

- Once the water material has been soaked, it doesn’t lose consistency, feature that hasn’t the plaster bandage when it is wet a lot.

- It has an elasticity which can be controlled. It retains its thickness and doesn’t lose its shape.

- Excellent approval, it isn’t sticky and doesn’t stain. It can be applied in an ulcerous process without any kind of protection.

- We can make the plantar support when the mold has been forged after fifteen minutes.

- It doesn’t shrink and it doesn’t withdraw.

These are the following advantages for the patient:

- It doesn’t cause allergic reactions.

- It is more pleasant for the skin than the plaster bandage soaked in cold water.

- Cutaneous surface easy to clean.

Thermoplastic bandage.

Making a note of measurements.

Application of heat on the bandage.

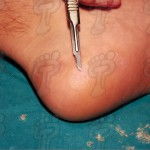

: Bandage adjustment on foot.

Correction control.

Correction control.

Negative mold (plantar view).

Negative mold (external lateral view).

Negative mold (back view).

Negative mold (internal lateral view).

Negative mold (front view).

Leave a Reply

Want to join the discussion?Feel free to contribute!